When Amway was founded in 1959, the company sold one product – a concentrated organic cleaner called Frisk known today as L.O.C.® cleaner, short for liquid organic concentrate.

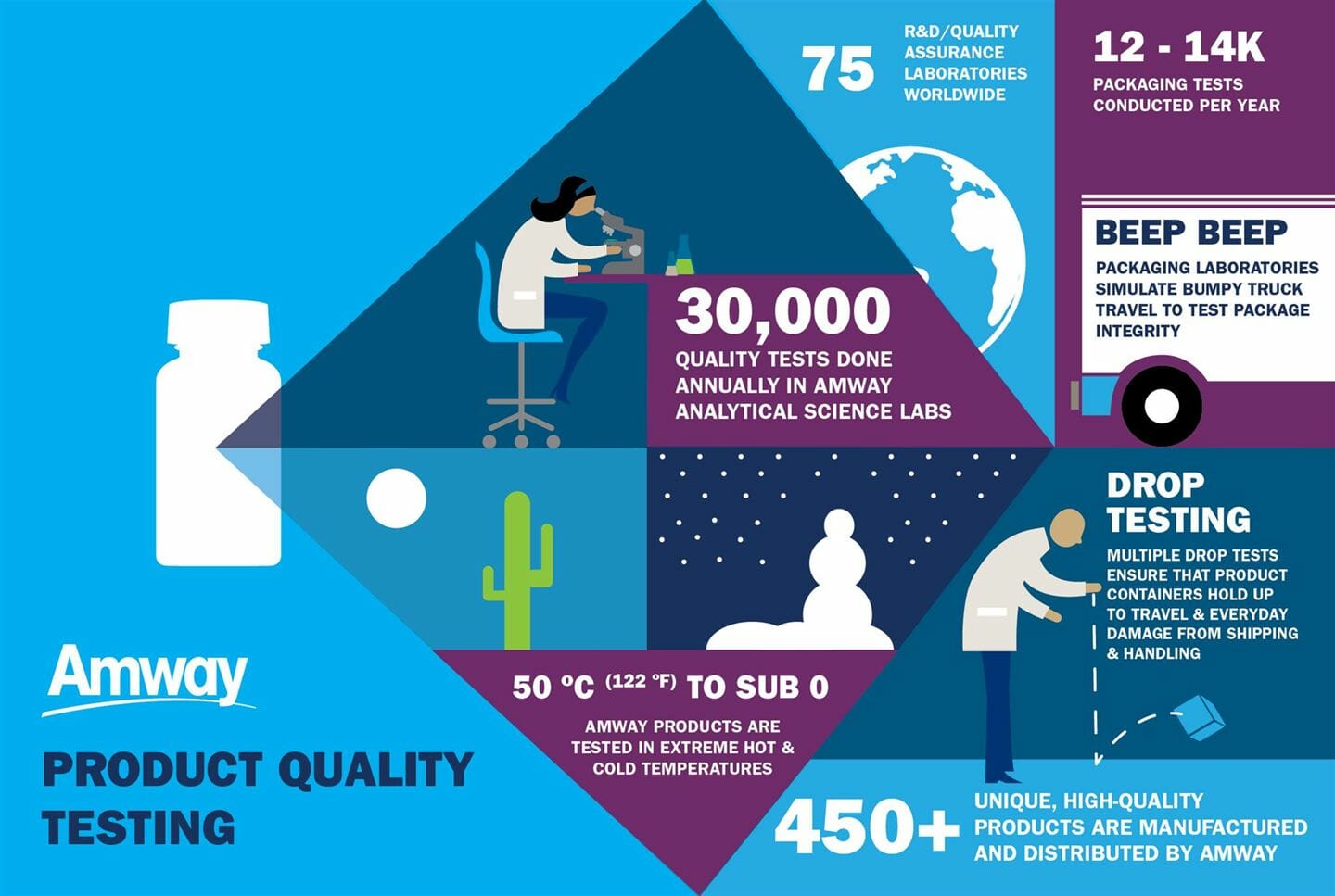

More than 55 years later, Amway sells more than 450 products in more than 100 countries and territories worldwide. Today, more than 900 scientists, engineers and technical professionals in 75 R&D and quality assurance (QA) labs around the world work every day to create and test Amway’s high-quality products.

To ensure health and beauty products are delivered to customers in optimal condition, Amway conducts a variety of checks including:

- The packaging labs conduct 12,000 to 14,000 tests annually – simulating bumpy truck travel to test package integrity, and performing multiple drop tests to ensure that product containers hold up to travel and everyday damage from shipping and handling.

- The QA labs conduct 30,000 quality tests every year, such as subjecting products to extreme heat (50 degrees Celsius) and sub-freezing (0 degrees Celsius) temperatures.

One of Amway’s QA labs, the Reliability Lab, puts products to the extreme test. The lab drops things, pounds things, burns things and throws things over and over and over again, using machines to simulate years of constant use.

“The Reliability Lab makes sure that when our products go out the door, they’re the best they can be,” said Amway QA Manager Mark Gammage.