The November issue of Popular Science features a collection titled: “The Worst Jobs in Science and Three Awesome Ones.”

The “worst” list includes trekking through snake-infested terrain in search of monkey dung, using axes and knives to slice and dice a moose carcass amid thousands of maggots and ticks and spending your days feeding rabbit blood to bed bugs.

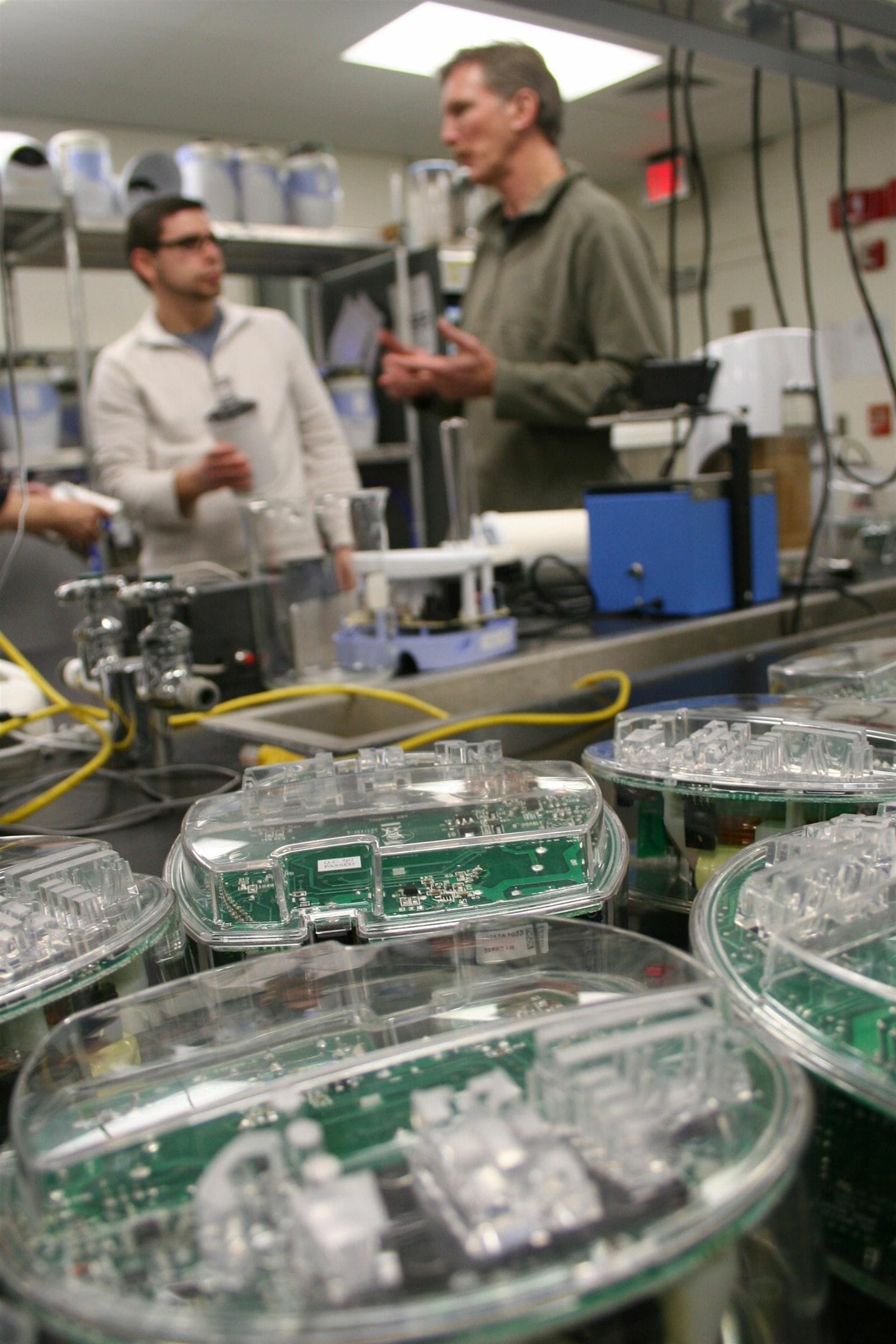

On the “best” list, however — right along side an ice cream flavor developer and a Corvette performance engineer — is our own “Room of Doom” Manager Mark Gammage and his team of extreme product testers in the Amway Reliability Lab. “The group’s real directive is to invent ways to torture and destroy everything the company makes,” the article states.

They drop things, pound things, burn things and throw things over and over and over again. They use machines to simulate years of constant use.

Gammage told Popular Science one of his favorite tests is looking for weaknesses in water-treatment tanks, pressurizing them until they blow up.

“You can hear it and see it as it explodes inside the protective clear case,” he said.

Sounds like fun, but it’s a serious job. As we wrote in a 2011, all the tests result in high quality products.

“The Reliability Lab makes sure that when our products go out the door, they’re the best they can be,” Gammage said.